- Back

- Balancing

- Capacity

- Charging

- Connections

- Data and operations

- Land and assets

-

Insight and innovation

- Back

- Home

- Insight and innovation

- Transmission innovation

- Summer Outlook

- Winter Outlook

- Gas Ten Year Statement (GTYS)

- Gas Future Operability Planning (GFOP)

- The future of gas-fired generation

- Understanding within-day behaviour

- Identifying future drivers of change

- Changing supply patterns

- Future of gas

- Stakeholder resources

Resource centre

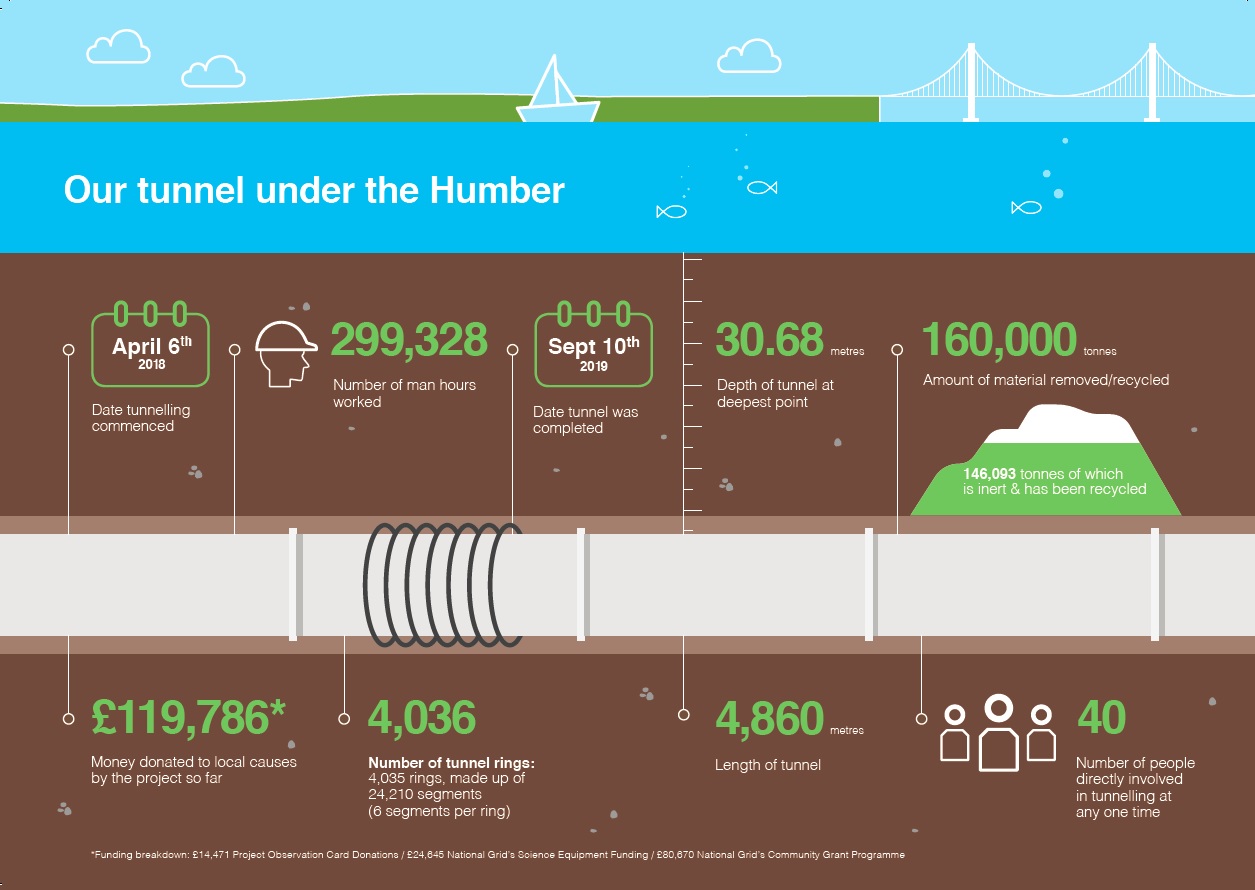

Welcome to the River Humber pipeline replacement resource centre.

National Grid B-roll Humber Walkthrough Tunnel – Winter 2019 footage.

Interview with Graham Boanas the first and only man to make history by walking over and under the River Humber through National Grid’s 5km tunnel.

National Grid B-roll Humber Walkthrough Tunnel – Winter 2019 footage.

A group of people descend at Paull shaft, walking through the 5km tunnel and finally emerge at Goxhill, includes soundbites from Graham Boanas.

National Grid B-roll Humber Walkthrough Tunnel – Winter 2019 footage.

Interview with Steve Ellison, Lead Project Manager for National Grid talking about the walk through the River Humber tunnel. Find out why the next stage of the project in Spring 2020 will be a world first.

Social Media Video

Graham Boanas makes history by walking over and under the River Humber through National Grid’s 5km tunnel. Watch from a unique perspective as Graham and National Grid’s project team make their way through the tunnel. The River Humber pipeline replacement project is set to break the record for the world’s longest hydraulically inserted pipeline.

An interview with Steve Ellison, Lead Project Manager, National Grid

An interview with Steve Ellison, Lead Project Manager, who explains how ‘Mary’, the TBM has been digging a tunnel to house a replacement gas pipeline 30 metres beneath the River Humber. See the final leg of Mary’s journey on this project, as she is carefully lifted out of the shaft at Paull and prepared for her onward journey.

B roll footage

B-roll footage of ‘Mary’ (tunnel boring machine) being lifted out of the reception shaft at Paull and being prepared for her onward journey.

Time-lapse of Mary in the reception shaft at Paull

After 18 months, we are finally able to see Mary, our Tunnel Boring Machine, again. The timelapse shows water in the shaft falling after Mary had completed an underwater tunnel breakthrough.

Mary our TBM breaking through

Mary, our tunnel boring machine has just completed her 18-month journey digging a 5km tunnel to replace a gas pipeline 30 metres beneath the River Humber. Here she is in the specially constructed shaft at Paull on the north bank.

Final ring time lapse video

Each ring is made up of six segments, installed by two ring builders. One operative controls the vacuum segment erector (lifting device) with the other operative guiding him using a measuring instrument. Once in place, it is bolted to the adjacent segments that form the ring. On completion of the ring, the TBM moves forward by using thrust rams.

Modelled fly through of the Humber River pipeline tunnel

The flythrough begins at Goxhill, the site for the TBM’s (Tunnel Boring Machine) launch shaft, which now serves as the main entrance of the tunnel. It then zooms across the River Humber, giving us a birds eye view of the tunnel, finally arriving at Paull, at the reception shaft, which is where the TBM has broken through.

Local Humberside hero, Graham Boanas leading the group on a 5km walk through the tunnel under the Humber Estuary.

Download image

Graham Boanas, the first person to walk over and under the River Humber, on his journey through the completed Humber Estuary Tunnel.

Download image

Humber Estuary Tunnel, electrical lights form rings leading to the end of the tunnel.

Download image

The cutter head being transported out of the site. This section of the TBM has been rotating for over 18 months digging the tunnel, now it’s going back for some refurbishment.

Download image

The tail skin is the final abnormal load. Once a tunnel ring was built it was pushed along this section of the tbm, at the end of which the ring would meet the newly excavated ground.

Download image

This is the section of the TBM that housed the thrusters and motors that helped push the TBM forward and rotated the cutting head. The front cavity is where the cutter head was placed. For transport purposes the cutter head had to be separated.

Download image

Mary (TBM) in the shaft at PaullMary our TBM, completes her 5km journey from Goxhill on the south side of the River Humber to the specially constructed shaft at Paull on the north bank.

Download image

A complete tunnel section. At the far end of the tunnel, operatives in there protective gear are carrying out works with the tunnel boring machine further behind them. The bagging above is the air duct, which feed fresh air to the tunnel. The pipes and cables on the left are electric cables, free washer pipes, grout pipes, slurry input and extraction pipes.

Download image

A welder in full protective gear is welding two sections of the new pipeline together, in preparation for the pipeline insertion in the tunnel.

Download image

Filling Paull Shaft with water from the boreholes. The water being pumped is clean and tested. The brown discoloration of the water in the shaft is the result of loss material in the shaft becoming freeborn. The circular ring which is partially submerged in the picture, is the portal that the tunnel boring machine entered the shaft.

Download image

The platform on the left is a ‘hop-up’ which operatives use as a safe area when multi service vehicles go past. The light at the end, is the entrance to the tunnel from Goxhill.

Download image

Paull Shaft

This is where the tunnel boring machine ‘Mary’ ended her journey. It also marks the end of the tunnel drive. The shaft is a 13.5 m deep and 15 m wide. For details of the shaft construction method, click here.

The sound of the tunnel boring machine

The sound of ‘Mary’, the Tunnel Boring Machine, breaking her way through the last metre of the tunnel, reaching the shaft at Paull.